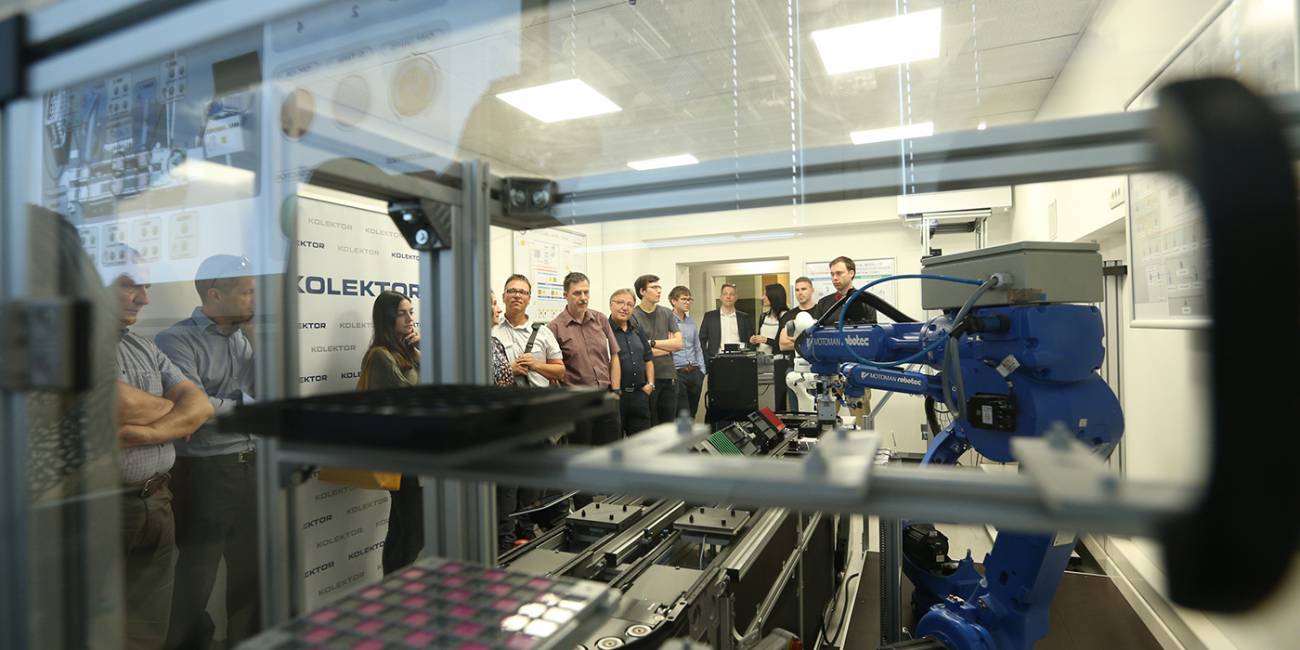

Opening of the first demo smart factory in Slovenia

06. 06. 2019

At the Faculty of Mechanical Engineering of the University of Ljubljana, a demonstration center "Smart Factory" was opened, which is the only and unique case in Slovenia, co-financed by Kolektor. It was created in line with the GOSTOP program, the largest program of the Smart Specialization S4 in the field of smart factories in Slovenia The idea of the demonstration center is in line with the basic idea of the smart specialization S4, which is to demonstrate the innovative application and deployment of Industry 4.0 technologies and the concept of a smart factory in a real industrial environment.

The demonstration center 'Smart Factory' is built on the concept of distributed systems and includes all important key technologies necessary for the operation of a smart factory. In this context, the backbone of the smart factory are a global digital twin and a global digital agent or artificial intelligence, supported by machine vision. Each process and system has its own digital twin and one or more digital agents, which, with the support of artificial intelligence, control processes and solve problems automatically at the local level, while all processes and activities are visualized and transparent. RFID technology enables the traceability of each process and ensures the communication between objects and subjects of the smart factory. In addition to robotized processes, the demo center also includes a smart manual workplace where it is possible to demonstrate the various smart factory technologies, such as virtual and augmented reality, digitization and transparency of installation or assembly instructions, the flexibility of assembly points and magazines, ergonomics of the workplace, etc. A smart factory in a demonstration environment enables completely flexible, agile and automatic planning and optimization of the work plan and the production process.

"We must realize that in the future organized manufacturing processes will be based on cybernetic connectivity, digital twins and digital agents, supported by artificial intelligence and other key technologies of the Industry 4.0. With the development and establishment of the center, an innovative scientific and research model has been put in place as a demonstration of a modern and actually functional example of the digitization of production processes,” explained Prof. Dr. Niko Herakovič, the founding leader of the demonstration center and head of the Laboratory for handling, assembly and pneumatics. Valter Leban, MSc, a member of the Board of Management of Kolektor, added: "A smart factory is only one that can also learn, not just carry out pre-programmed tasks. The mere automated factory is therefore not smart, because it does not work according to the principle of sense-think-act.”

Back