The innovation of the line enables broader range of metalized products

19. 12. 2019

Kolektor ATP developed an automatic line R2R with modular components that, thanks to its innovative modular design, enables easier adaptation to customers’ needs.

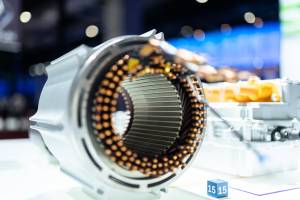

The electric car industry has been booming in recent years and the need for various hybrid components has increased. In most hybrid components, the contacts are coated or metalized with various metals. Most of these components are metalized on the so called reel-to-reel lines (hereinafter referred to as the R2R) where an endless strip travels through different tubs where metalization takes place. Such line was developed in Kolektor ATP.

»New strip metalization line is a very important asset for our program of hybrid components,« says Marko Vihtelič, Managing Director of Kolektor ATP, and adds that they have recently acquired several new projects for the automotive industry that require selective metalization on the metal part of the product. “This technology is key to our products and there are currently only a few manufacturers in Europe for selective strip metalization, which, due to their lack of production capacity, have very long delivery times. Their capacities must be reserved up to one year earlier. These delivery times have recently been reduced to a few months, but still. This line will now give us more flexibility and significantly shorter deadlines for this service, which is also used by our other factories across Europe. Furthermore, winning this process and the innovation of this line give high added value to our finished product.”

Back