Productivity increased by 8%

User profile

- Client: a Slovenian discrete manufacturing company.

- Industry: automotive.

- 200+ employees.

- Product: integration with ERP (SAP) system and company’s control system.

Customer's challenges in production

- Low efficiency of production lines.

- Variable product quality.

- Lack of available capacity.

- High labor and inventory costs.

- Low OEE.

Solution

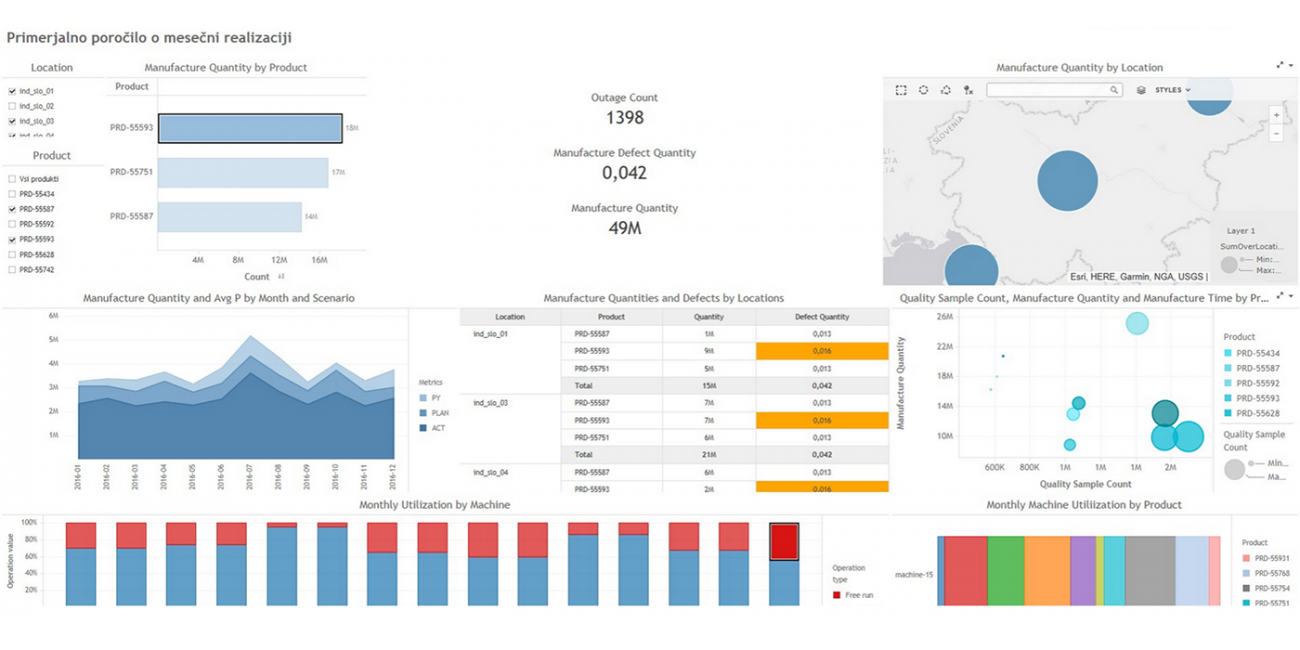

- Intelligent production planning and alarm in case of deviations in real time.

- Predicting organizational congestion and proposing corrective measures.

- Optimized automatic scheduling of work orders and employees.

- Comparison of different scenarios for the implementation of the production plan.

- Automatic and accurate forecasting of demand and sales.

- Optimization of inventory turnover.

Key benefits for the customer

- Productivity increased by 5-8%.

- Production return higher by 15-25% thanks to less waste or material residues and lower processing costs.

- Warranty costs due to product defects reduced by 10-20%.

- Utilization or return on assets (ROA) improved by 3-5%.

- Achieving the productivity of new or skilled workers faster.

- Greater employee flexibility and satisfaction.

- Improved operational efficiency.

- Less work with ensuring compliance and traceability.

Contact us

Back