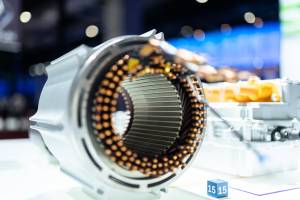

Complex hybrid part for control system

User profile

- Client: a global manufacturing company, Tier 1 supplier.

- Industry: automotive.

- Product: complex hybrid part for control system.

Challenges

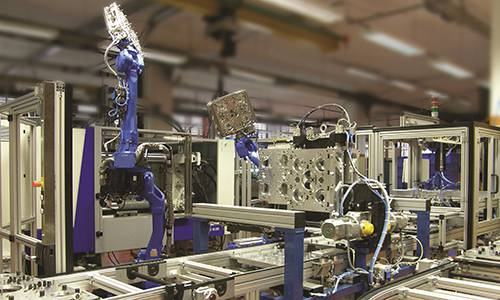

- Development of fully automated stamping, forming and final assembly processes.

- Very complex processes, high requirements for accuracy, repeatability and consistency.

- It was necessary to ensure a 100% product quality control.

- High requirements for cleanliness in production area.

Solution

- A comprehensive innovative solution for robotically supported processes.

Key benefits for the customer

- Full traceability of all components and data in processes.

- Drastically faster production cycles (4.5 s).

- Availability of devices > 90 %.

- Fully lean production line.

- Autonomous self-inspection of processes (precise optical inspection, inspection of electronics).

- Precise fine mechanics / assembly.

Contact us

Back