Magnetics

- Kolektor >

- Kolektor Mobility >

- Magnetics

We produce 250 million magnets per year

Kolektor is one of the leading producers of permanent plastomagnets based on ferrite materials and rare earths, which are an integral part of electric motors and sensors. They are primarily intended for use in the automotive industry and industrial technology.

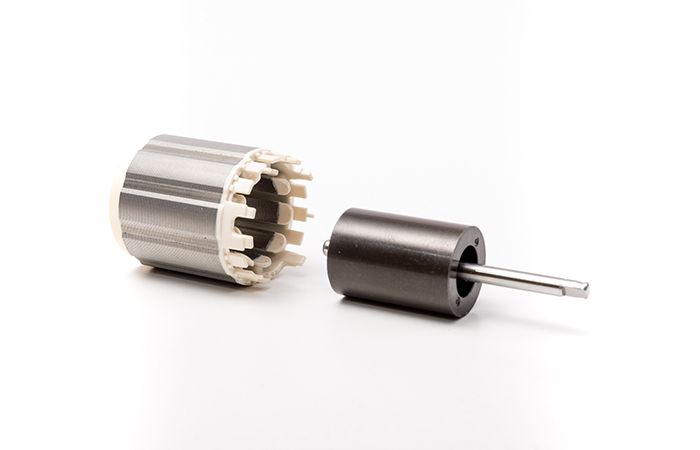

Magnets for rotors

Rotors are one of three vital components of a brushless motor. With the use of permanent magnets, they ensure continuous magnetic field, which in interaction with the field of stator coils and suitable controller enable optimal continuous operation.

Material choices for rotor applications include variety of sintered or polymer bonded magnets covering a range of materials such as Ferrite, Nd-Fe-B, Sm-Co or Sm-Fe-N. Depending on requirements, a variety of magnetisation patterns covering bi- or multipolar topologies is feasible.

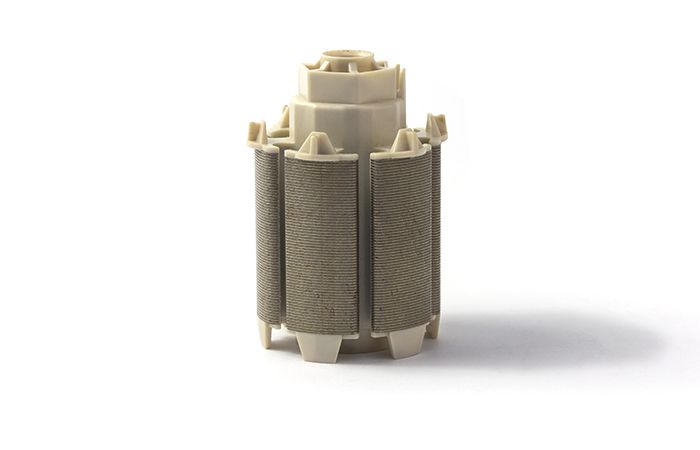

Sensor magnets

In automotive and industrial applications permanent magnets in connection with sensor electronics serve as an information provider with reference to position, level, linear or rotational movement, proximity, frequency and many others.

The sensoric systems convert this information to physical values of mass flow (solid, liquid, gas), speed of rotation or linear shift, torque, angle and many others.

Depending on requirements a range of magnetic materials (Ferrite or Rare-Earth based) and manufacturing technologies including injection and compression moulding, sintering, over and insert moulding or glue-bonding are available.

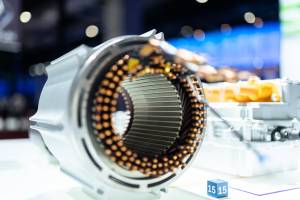

Stators

Stator is one of the key components of BL motor. In connection with controller, it generates a changing magnetic field in the motor and, in interaction with rotor, enables its rotation and torque transmission to the shaft. With different topologies and winding schemes, it enables motor optimization and operation adapted to a specific operating point.

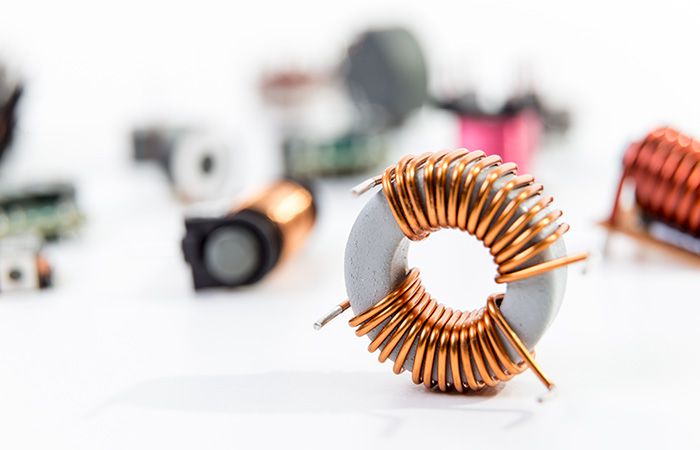

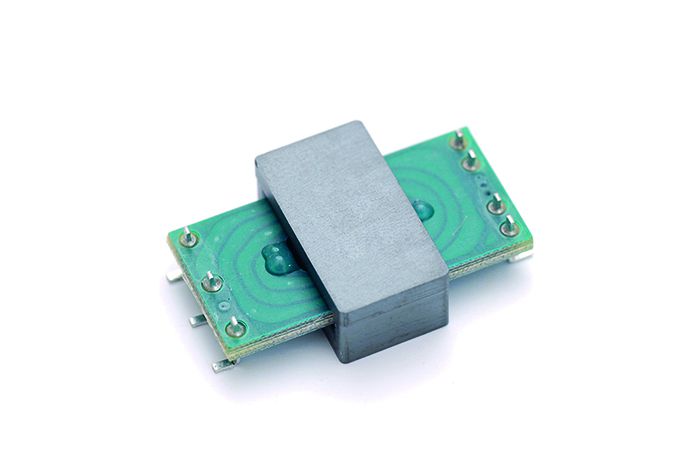

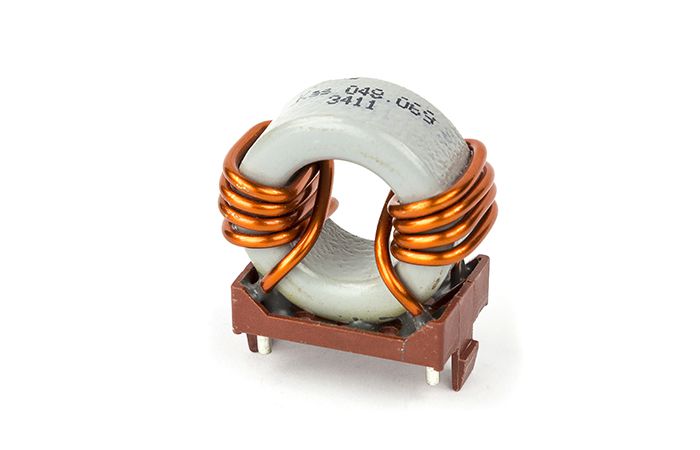

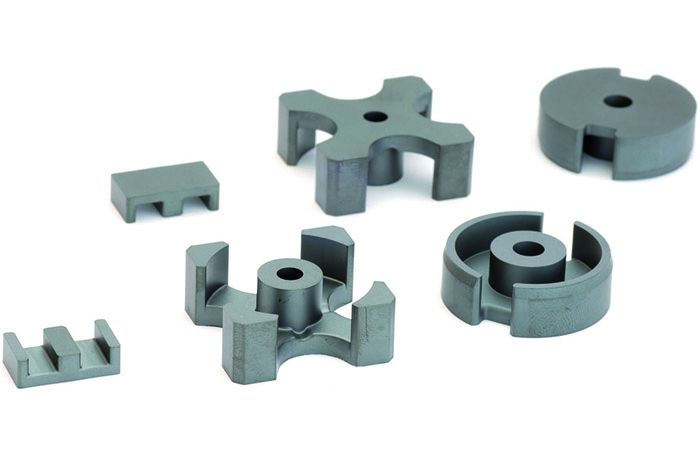

Inductive components

Inductive components are an important element of electronic sub-systems and contain ferrite cores – mostly of proper production.

Application examples: voltage transformers, exterior and interior illumination of vehicles, reduction and/or elimination of high-frequency interferences, motor controls, pressure control in pneumatics, RFID identification, detection of metals and coins, other

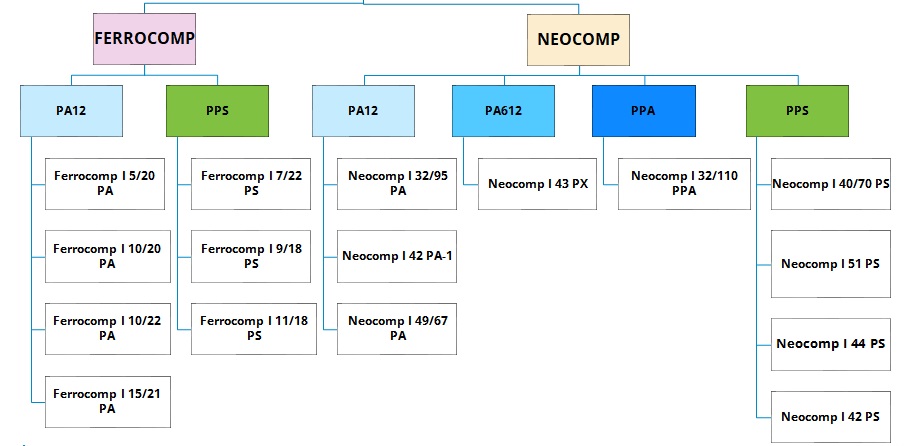

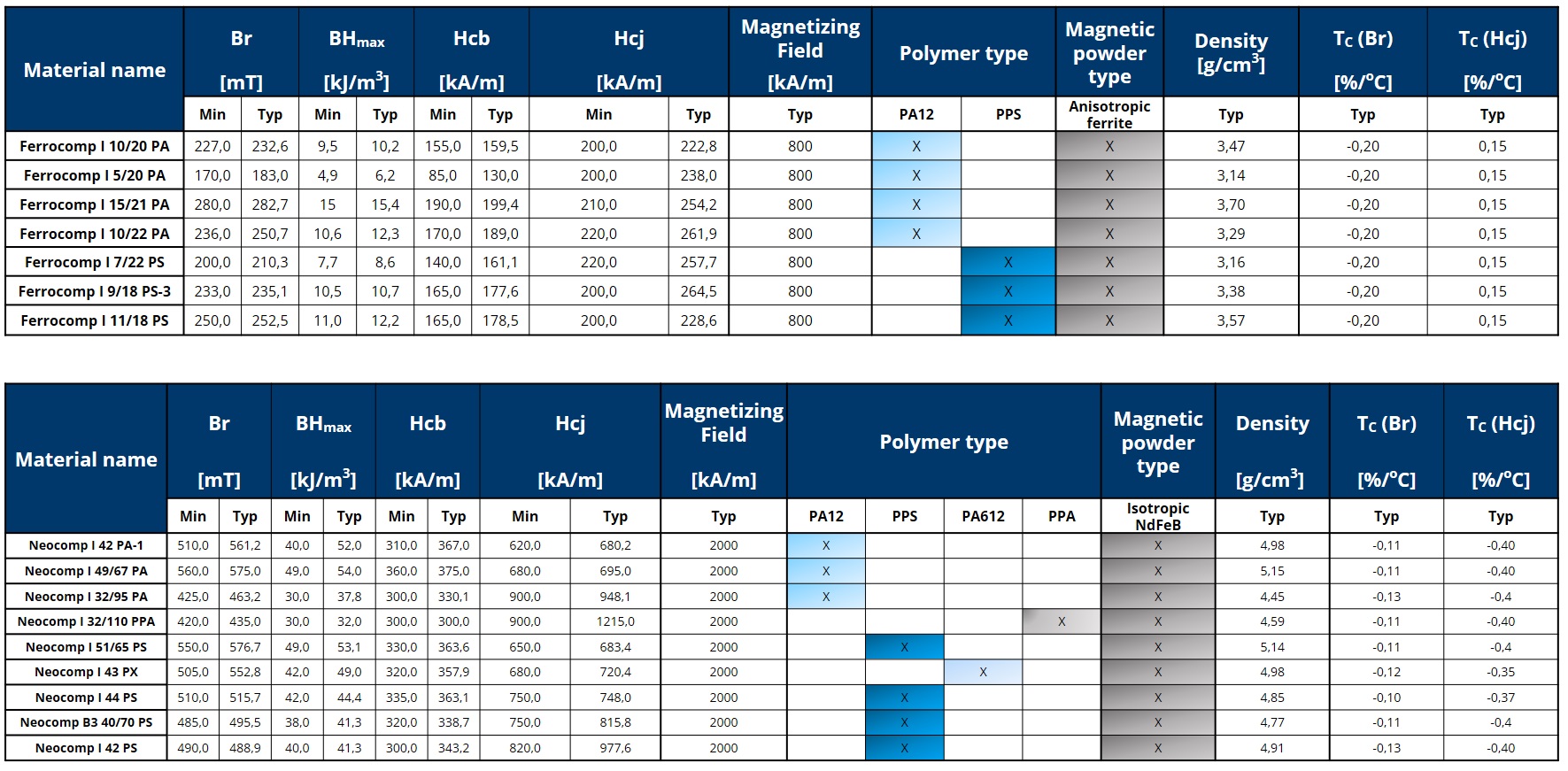

Polymer bonded magnet materials for injection molding

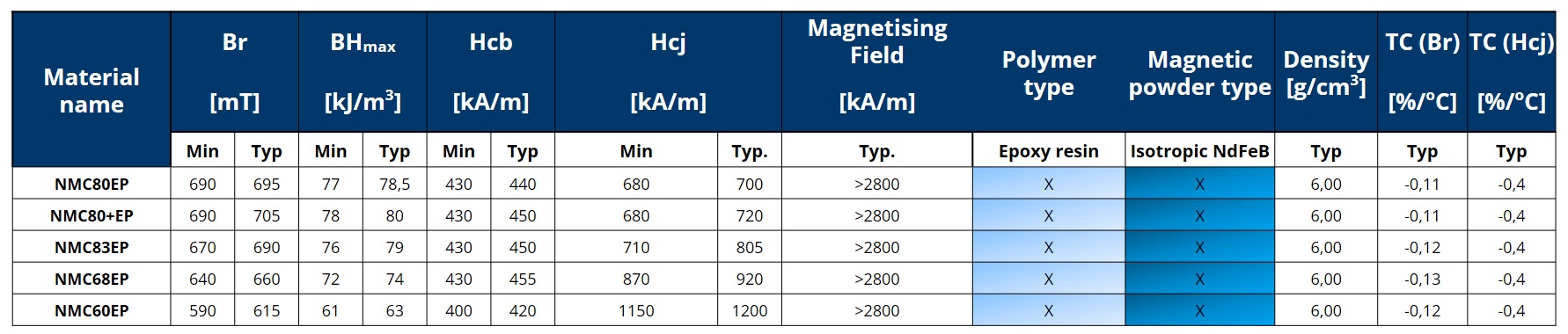

Polymer bonded magnet materials for pressing

Magnetic and Mechanical characteristics

- Magnetic properties are measured on standard samples according to IEC 60404-5. Dimensiones of cylindrical samples are: heigh of 7 mm, diameter of 10 mm.

- Mechanical properties are measured on standard samples according to ISO 527-2/Type 1B.

- Flexural strenght is measured according to internal standard.

- Tensile strength is measured according to ISO 527.

- Density measurements are determined according to ISO 1183, method A.

- Melt flow rate is determined according to internal standard.

- Magnetic and mechanical properties of NMC materials, are measured on magnets of cylindrical shape, height of 10mm and diameter of 16mm.

Key solutions

- combinations of magnetic material and geometry approved under various combinations of physical parameters (time, T, pressure, concentration)

- geometry and strength of a magnetic field defined during injection molding

We offer

- simulation calculation as to magnetic systems

- tool construction

- measuring of magnetic properties

- testing of the magnetic material

- customer support from an idea to post-marketing activities

Why work with us

Competences

Tehnological

- manufacture of magnetic components of NdFeB, hard-ferrite and mix of NdFeB and hard-ferrite by means of compressed moulding and injection moulding

- development and manufacture of compounds for injection moulding of magnets

- manufacture of soft-magnet cores by means of compressed moulding and injection moulding

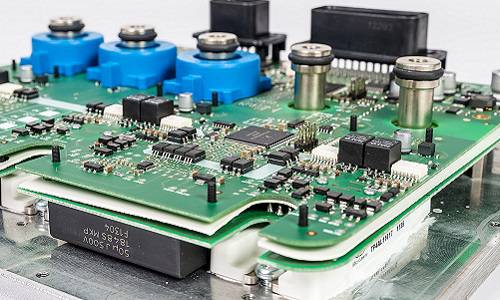

- optimization of electronic and magnetic sub-systems

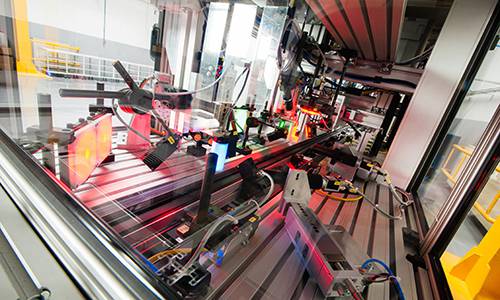

- state-of-art development and production equipment

Organizational

- highly professional and experienced personnel in the field of magnetism

- certified management systems (ISO 9001, ISO 14001, IATF 16949)

- cooperation with customers in development projects

- reliable partner

Advantages

- ensured short time from an idea to the actual product

- variety of magnetic materials

- technology of composites

- integral solutions

- different production locations

- vertical integration in the group from raw material to products

- wide supplier net for strategic raw materials

- developmental partner with most of the customers

- production flexibility (small- and large-series production)

Contact us

Together we can find the right solution